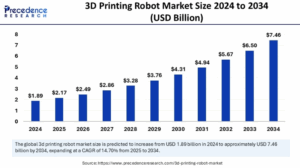

The global 3D printing robot market size was estimated at USD 1.89 billion in 2024 and is expected to hit around USD 7.46 billion by 2034, growing at a CAGR of 14.70%.

The 3D printing robot market is experiencing strong growth, driven by increasing government support for additive manufacturing. Combining robotic arms with advanced printing technology, these robots enable automated construction of complex structures. They are widely used across industries like automotive, aerospace, and construction for prototyping, tooling, and production. Growing adoption in the defense sector to speed up equipment development further accelerates market expansion.

3D Printing Robot Market Key Takeaways

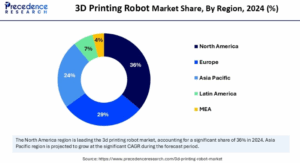

- North America dominated the 3D printing robot market with the largest share of 36% in 2024.

- Asia Pacific is anticipated to witness the fastest growth during the forecast period.

- By component, the robot arms segment held the dominant market share in 2024.

- By component, the software segment is expected to grow at the fastest rate between 2025 and 2034.

- By robot type, the articulated robots segment held the largest share of the market in 2024.

- By robot type, the SCARA robots’ segment is projected to grow at a significant CAGR over the studied years.

- By application, the prototyping segment led the global market in 2024.

- By application, the functional part manufacturing segment is projected to expand rapidly in the coming years.

- By end-user, the aerospace & defense segment dominated the market in 2024.

- By end-user, the construction segment is projected to grow at a notable rate in the near future.

3D Printing Robot Market Regional Outlook

The global 3D printing robot market size accounted for USD 1.89 billion in 2024 expanding at a CAGR of 14.70% from 2025 to 2034. North America dominating with largest market share of 36% in 2024. This dominance is attributed to substantial investments in additive manufacturing, robust R&D initiatives, and a well-established industrial infrastructure.

Asia Pacific is anticipated to witness the fastest growth in the 3D printing robot market with market share of 24%. The rising focus on industrial automation and improving manufacturing capabilities are expected to boost the growth of the market in the region.

Europe is expected to witness notable growth in the 3D printing robot market over the coming years with market share of 29% in 2024, driven by the increasing demand for additive manufacturing across various industries. This growth is fueled by the need for sustainable production practices, the use of lightweight materials, and the growing preference for customized solutions. A significant milestone underscoring the region’s technological advancement was achieved in September 2024, when the European Space Agency (ESA) successfully launched a metal 3D printer to the International Space Station (ISS), highlighting Europe’s commitment to innovation and advanced manufacturing. While Latin America contributes market share of 7% and MEA of 4% in 2024.

What is U.S. 3D Printing Robot Market Size?

The U.S. 3D printing robot market size was exhibited at USD 510 million in 2024 and is projected to be worth around USD 2.060 million by 2034, growing at a CAGR of 14.98% from 2025 to 2034.

3D Printing Robot Market Trends

- Hybrid Manufacturing Solutions: The integration of 3D printing capabilities into robotic systems enables the creation of hybrid manufacturing solutions that combine additive and subtractive processes. Hybrid 3D printing robots offer enhanced versatility, allowing for the fabrication of complex geometries, multi-material components, and finished products with superior surface finish and accuracy.

- On-Demand Production and Customization: 3D printing robots facilitate on-demand production and customization of products, empowering manufacturers to respond quickly to changing market demands and customer preferences. By leveraging robotic automation and digital design technologies, companies can achieve greater flexibility, reduce lead times, and offer personalized products tailored to individual needs.

- Industry 4.0 Integration: 3D printing robots play a pivotal role in the implementation of Industry 4.0 principles, driving the digitalization and automation of manufacturing processes. Integration with IoT (Internet of Things) technology, AI (Artificial Intelligence), and cloud-based platforms enables real-time monitoring, predictive maintenance, and remote control of robotic 3D printing systems, optimizing production efficiency and productivity.

- Advancements in Additive Manufacturing: Technological advancements in additive manufacturing processes, materials, and software solutions fuel the adoption of 3D printing robots across industries. Continuous innovations in 3D printing technologies, including multi-material printing, high-speed printing, and metal 3D printing, expand the application potential and market opportunities for robotic additive manufacturing systems.

- Demand for Complex Geometries and Lightweight Structures: The growing demand for complex geometries, lightweight structures, and optimized designs drives the adoption of 3D printing robots in industries such as aerospace, automotive, and healthcare. Robotic 3D printing enables the production of intricate components, lattice structures, and functional prototypes with enhanced performance, reduced weight, and improved material utilization.

- Expansion in the Healthcare Sector: The healthcare industry presents significant opportunities for 3D printing robots. These robots can be used to produce customized medical devices, prosthetics, and implants tailored to the needs of individual patients.

- Growth in Construction and Architecture: Another significant opportunity lies in the construction and architecture sectors, where 3D printing robots can revolutionize the way buildings and infrastructure are designed and built. Robotic 3D printing can enable the creation of customized building materials, intricate architectural designs, and even entire buildings. These robots can also automate tasks such as bricklaying or concrete pouring, enhancing efficiency and reducing labor costs in the construction industry.

- Integration with Artificial Intelligence (AI) and Machine Learning: The future of 3D printing robots will likely see greater integration with AI and machine learning algorithms. These technologies can improve the robots’ ability to autonomously optimize designs, adapt to complex requirements, and monitor and adjust the printing process in real time. Machine learning could enable robots to “learn” from previous prints, improving their accuracy and efficiency with each use.

- Sustainability and Eco-Friendly Printing Solutions: As industries focus more on sustainability, 3D printing robots will be increasingly utilized to reduce waste and improve energy efficiency. These robots can create products with minimal material usage, and their ability to print complex geometries leads to less waste during production. Additionally, 3D printing robots can use recycled or biodegradable materials, contributing to the development of environmentally friendly manufacturing practices. Sustainability will be a major focus in the design and operation of future 3D printing robots, with a focus on reducing environmental impact.

Component Outlook

The robot arms segment led the 3D printing robot market in 2024, driven by their exceptional versatility and precision in executing additive manufacturing tasks. These robotic arms can print complex, large-scale structures—often exceeding one meter—using five or six-axis movements to create detailed components without the need for support systems. Their adaptability makes them suitable for a range of manufacturing applications, including large-format concrete 3D printing, revolutionizing industrial-scale production.

Meanwhile, the software segment is projected to grow at the fastest pace over the coming years. Growth is fuelled by the increasing demand for advanced software that enables seamless integration of 3D printing robots into production environments. Key features such as real-time process control, automated path planning, error detection, and performance optimization enhance printing precision and efficiency. As adoption of 3D printing accelerates across industries, the need for intelligent software solutions that reduce costs and ensure consistent output continues to rise.

Robot Type Outlook

- In 2024 the articulated robots segment held the largest share of the 3D printing robot market in 2024, driven by their exceptional versatility and precision. Equipped with multiple rotary joints and five- or six-axis movement, these robots offer superior maneuverability, allowing the creation of large, complex components without the need for additional support structures. Their widespread adoption in the automotive and aerospace industries reflects their effectiveness in producing intricate designs while enhancing overall production efficiency.

- The SCARA robots’ segment is expected to grow at a significant CAGR over the forecast period. SCARA robots feature a parallel-axis joint design that offers X-Y compliance and Z-axis rigidity, making them ideal for precise and delicate tasks. With their four-axis configuration including two parallel arms and a rotational end-effector they are well-suited for complex 3D printing operations. SCARA robots also support automated post-processing functions such as support removal and inspection, and their ability to handle multi-material printing makes them a valuable asset in expanding 3D printing capabilities.

Application Outlook

- In 2024 the prototyping segment led the 3D printing robot market, driven by the growing demand for rapid prototyping to speed up product development. 3D printing robots enable the fast creation of complex prototypes, allowing multiple design iterations and accelerating time-to-market. This capability supports faster production cycles and higher output across industries.

- The functional part manufacturing segment is expected to grow rapidly in the coming years, fueled by advancements in materials and printing technologies. Automated 3D printing systems are increasingly used to produce high-strength, customized parts with complex geometries that are difficult to achieve through traditional methods. This segment is vital to completing production workflows, particularly in the aerospace and automotive sectors, where demand for durable and precision-engineered components continues to rise.

End-user Outlook

- In 2024 the aerospace & defense segment held the largest share of the 3D printing robot market, driven by the growing demand for lightweight, high-performance components with complex geometries. These industries rely on 3D printing robots to manufacture efficient aircraft structures and durable defense equipment. The technology enables the production of customized, intricate parts, reducing tooling needs, minimizing material waste, and cutting overall production costs. Additionally, increased defense spending to enhance infrastructure has further supported segment growth.

- The construction segment is expected to grow at a notable pace in the coming years, fueled by the rising adoption of automation in construction activities. 3D printing robots are increasingly used to construct cost-effective structures using durable materials while reducing labor dependency. These robots can build entire structures with minimal human intervention. A significant milestone was achieved in March 2025, when Australia began constructing its first 3D-printed multistory house using robotic cranes, showcasing the segment’s potential.

Recent Developments

- In January 2024, RIC Technology introduced its latest innovation, the RIC-M1 PRO, a compact modular robotic arm printer, at the World of Concrete (WOC) 2024. This upgraded printer features a wider footprint than previous versions, improved automation, and an intelligent material delivery system. According to RIC Technology, the RIC-M1 PRO offers a cost-effective, time-saving solution that minimizes labor requirements—specifically targeting the global housing shortage.

- In April 2024, Meltio, a metal 3D printing technology developer, partnered with Michigan-based automation firm Accufacture to launch Alchemist 1. This large-scale robotic Directed Energy Deposition (DED) 3D printing workcell is built in the U.S. and uses Meltio’s Laser Metal Deposition (LMD) technology. Alchemist 1 is designed to manufacture fully dense, large-scale metal components and can be seamlessly integrated into existing production lines.

- In February 2025, ENCY Software released version 1.0.5 of its ENCY and ENCY Robot platforms. The update brings a suite of new features to enhance additive manufacturing processes. A key addition is the corner feed feature, which gives users full control over extrusion and deposition rates throughout the printing process. This capability is aimed at reducing material waste, boosting efficiency, and minimizing post-processing work.

3D Printing Robot Market Companies

- Arcam AB

- EOS GmbH

- Materialise

- Prodways Technologies Group

- Renishaw plc

- SLM Solutions Group AG

- Stratasys