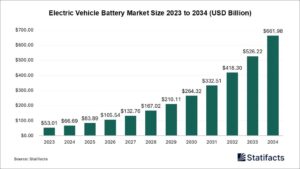

The global electric vehicle battery market size was surpassed USD 66.69 billion in 2024 and is predicted to hit around USD 661.98 billion by 2034, expanding at a CAGR of 25.8% from 2025 to 2034

The electric vehicle (EV) revolution is well underway, with advancements in battery technology driving its rapid adoption. As global efforts to combat climate change intensify, the demand for efficient, long-lasting, and sustainable EV batteries has never been higher. In this blog, we will explore the latest developments in EV battery technology, the challenges faced by manufacturers, and what the future holds for this crucial component of the green mobility movement.

Understanding EV Batteries

At the heart of every electric vehicle is its battery pack, which serves as the primary power source. The most common type of battery used in EVs today is the lithium-ion battery, valued for its high energy density, efficiency, and relatively long lifespan. However, as the industry expands, alternative battery technologies are being explored to enhance performance, reduce costs, and minimize environmental impact.

Key Innovations in EV Battery Technology

- Solid-State Batteries Solid-state batteries represent the next frontier in EV technology. Unlike conventional lithium-ion batteries that use liquid electrolytes, solid-state batteries employ solid electrolytes, offering higher energy density, faster charging times, and improved safety. Companies like Toyota, QuantumScape, and Samsung are heavily investing in solid-state battery research to bring these cutting-edge power sources to market.

- Lithium-Sulfur Batteries Lithium-sulfur (Li-S) batteries are gaining traction due to their potential to provide significantly higher energy storage capacity than traditional lithium-ion batteries. They also rely on abundant and inexpensive sulfur, making them a more sustainable and cost-effective alternative.

- Cobalt-Free and Sodium-Ion Batteries The reliance on cobalt in lithium-ion batteries has raised concerns due to ethical sourcing issues and supply chain constraints. Researchers are actively working on cobalt-free lithium-ion batteries and sodium-ion batteries, which offer a more sustainable and cost-efficient solution without compromising performance.

- Faster Charging and Longer Lifespan Battery manufacturers are developing new charging solutions to reduce charging times significantly. Technologies like silicon anodes and advanced thermal management systems help extend battery lifespan while ensuring rapid charging, addressing one of the key consumer pain points in EV adoption.

Rising Mega-Trend of Electrification to Propel Market Growth

The rapid shift toward electrification is a key trend shaping the market. Government initiatives focused on establishing a robust network of EV charging stations and enhancing the EV ecosystem are expected to drive the adoption of emission-free mobility, thereby influencing the global EV battery market. Additionally, the growing emphasis by original equipment manufacturers (OEMs) on expanding electrification efforts is further contributing to market expansion.

A significant number of leading automakers worldwide have outlined concrete plans to scale up production of their existing electric vehicle lineup and introduce more models. The surge in Battery Electric Vehicles (BEVs), equipped with large lithium-ion batteries, and Plug-in Hybrid Vehicles (PHEVs) on the roads is expected to necessitate the development of high-power charging infrastructure in the coming years. These factors will accelerate EV adoption and subsequently boost battery demand across major markets.

Challenges Facing EV Battery Development

Despite significant advancements, the EV battery industry faces several challenges:

- Raw Material Supply Chain: The production of lithium-ion batteries depends on critical raw materials such as lithium, cobalt, and nickel, which face supply chain limitations and geopolitical risks.

- Recycling and Sustainability: Battery recycling remains a complex process. Developing a circular economy for EV batteries through efficient recycling methods is crucial for long-term sustainability.

- Charging Infrastructure: The expansion of fast-charging networks is necessary to support widespread EV adoption, reducing range anxiety and making EVs a viable alternative to internal combustion engine vehicles.

- Cost Reduction: Battery costs remain one of the largest expenses in EV production. Scaling up production, optimizing battery chemistry, and improving manufacturing processes are essential to make EVs more affordable.

The Future of EV Batteries

Looking ahead, continued investment in research and development will unlock new possibilities for EV batteries. Breakthroughs in next-generation battery chemistry, enhanced energy storage solutions, and improved sustainability practices will drive the industry forward. Governments and automakers worldwide are setting ambitious targets for electrification, further accelerating innovation in battery technology.

As we transition toward a greener future, the evolution of EV batteries will play a pivotal role in shaping the success of electric mobility. By overcoming current challenges and embracing cutting-edge advancements, the industry is poised to deliver more efficient, affordable, and eco-friendly battery solutions that will define the next era of transportation.

Electric Vehicle Battery Market Companies:

- CATL

- Panasonic

- LG Chem

- BYD

- Samsung SDI

- Johnson Controls

- GS Yuasa

- Hitachi Group

- Automotive Energy Supply

- Blue Energy

- Lithium Energy Japan

- Bosch

- Wanxiang

- Beijing Pride Power

Electric Vehicle Battery Market Segmentation:

By Type

- Lead-acid Batteries

- Lithium Battery

- Others

By Application

- BEV

- HEV

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa